Lacquer Sanding

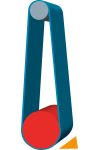

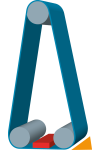

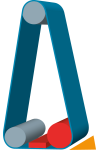

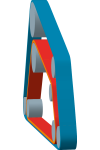

Our oblique sanding technology has originally been developed to improve intermediate lacquer sanding using a widebelt sander. Compared to the widespread parallel sanding technology the advantages are very apparent. Then, there is also the widely known cross belt technology. The idea behind a sanding belt running transversally to the conveyor direction is to erase traces along the length of the workpiece generated by a previous sanding unit. If this previous unit is an oblique one, which innately creates almost no sanding traces, the combination of the two makes for superb high gloss lacquer sanding quality.

In addition, the improved cutting-ability of the sanding grain that is generated by the "shearing cut" thanks to the oblique technology, brings even more advantages with regard to intermediate sanding:

Better surfaces, demonstrably

According to actual users, the oblique sanding technology is especially good for lacquer sanding. The Idea of the last sanding belt running slightly diagonally to the conveyor direction is to eliminate the parallel sanding traces of the previous unit which is usually a typical parallel one. The combination of an oblique sanding unit with a cross-belt high gloss unit even improves the surface quality on high gloss lacquered pieces.

These are scientifically sound facts: When Dr.-Ing. Ingrid Fuchs from the Wood Technology Institute in Dresden did tests on surface roughness, she found: "The fact that roughness values are smaller when using the oblique sanding technology as opposed to the classic parallel sanding technology is clearly visible."

…roughness values are smaller when using the oblique sanding technology as opposed to the classic parallel sanding technology

- Dr.-Ing. Ingrid Fuchs, IHD Dresden

Units

| Fine Sanding Roller Gd | Sanding Pad Ed | Combi Unit Cd | High Gloss Unit H | Ultra High Gloss Unit Hg |

|---|---|---|---|---|

|

|

|

|

|

| Large fine Sanding Roller oblique | Pad Brilliant oblique electronically controlled | Combined Unit Roller/Pad oblique, segmented and electronically controlled |

High Gloss Cross-Belt unit at Machine Outlet | Ultra High Gloss Cross-Belt unit with extra long belts |

Working Widths

| 650 mm | 1100 mm | 1350 mm | 1600 mm | 1900 mm | 2200 mm |

Other working widths on request

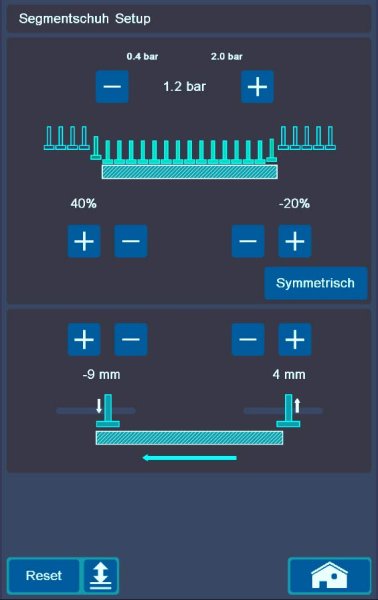

Segmented Pad Controls

A segmented sanding pad is in an integral component of any lacquer wide belt sander. At Kundig, we do not only use 22mm (1 Inch) thin workpiece detecting rollers but the same small 22mm size sanding segments as well. Our software allows for easy and logical control of this complex precision-intrument. In the upper part of the screen the overall sanding pressure is adjusted. Below, the pressure on the workpiece edges can be regulated in percentage increments. Additional segments can even be added or subtracted on each side. Asymmetric adjustments, which means different edge pressure on each side, are possible as well. In order to specifically concentrate on either the front or rear end of the workpiece, the activation and retraction of the sanding segments can either be delayed or accelerated, which is easily controlled in the bottom window.

Behind this software is a refined control system that converts those user inputs with millisecond precision. This allows for accurate segment activation even at extremely high feed speeds (for example in furniture industry applications). This technology is available in our parallel, oblique and cross belt units.

Cross Belt Units

For certain applications, a cross sanding unit proves to be the perfect choice. For example, an unparalleled finish can be achieved on high-gloss lacquered parts, especially in combination with our patented oblique sanding technology. For this purpose we offer a selection of different cross belt units, alternatively integrated in the machine body or at the machine exit.

We are achieving optimal results with our reference sanding machine...

- Elmar Kaiser, Remmers Farben & Lacke, Deutschland

KUNDIG Flash

Edge sander for lacquer edges

The Flash is the only edge sander with an actuated sanding pad similar to wide belt sanders.

This electronically controlled, pneumatic pad is spring loaded and adheres to those delicate high gloss edges smoothly. Its activation can easily be accelerated or delayed in order to prevent rounded or damaged corners.

The infinitely variable conveyor belt and sanding belt speed allow for a perfect fine tuning to the lacquer that is used. Thanks to its sensitivity and precision the Flash is, according to the statements of experienced users, without alternative in its field.