Project: Technic-Perform-6 - Master of every Discipline

Standard machines such as our recently launched base model Master and the top-of-the-range joinery model Perfect are currently in great demand, but there is also a trend among joiners towards ever more lavishly equipped machines. In addition to industrial plants and special applications, joineries have increasingly ordered very versatile configurations from us in recent years. The Technic-6 recently delivered to a large joinery is a true feast of sanding technologies and thus a perfect example of this trend.

The sanding units...

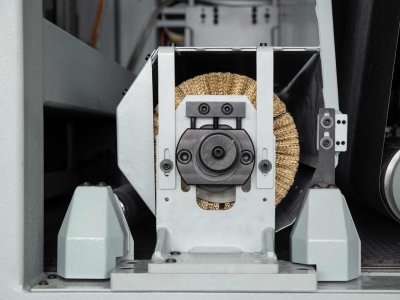

The first two sanding units are a classic calibration unit and a combi unit that can be used for either calibration or fine sanding. In fifth place, a pure segmented sanding pad with the Kundig exclusive diagonal sanding technology ensures excellent fine sanding. Finally, there is the compact cross sanding unit X, which, especially in combination with the preceding diagonal sanding technology, produces unparalleled lacquer surfaces or a perfect sanding on cross veneer. Equipped with a coarse-grained sanding belt, the cross belt is also suitable for producing a rough sawn structure. Speaking of texturing: The brushing unit installed in the third position can be optionally equipped with steel brass or Anderlon bristles and is available in oscillating and fixed variants. This makes textured surfaces possible on all hard and soft woods. The following disc brush unit is used for scratch-free sanding of workpieces with different grain directions, as well as for sanding out recesses and rounding edges.

...in perfect interaction

With this equipment, extremely specific machining is possible for practically every conceivable application, even for batch size 1 as part of a production line. You can rely on a large number of intelligent automatic mechanisms or, alternatively, experiment yourself with the help of our intuitive control system. For cleaning workpieces and sanding belts, the innovative Eco Cleaning System is used, which completely eliminates the need for expensive compressed air.